In early January, a federal agency alert made clear what many already knew: that crude oil from the Bakken formation is more prone to explosion than other types of crude oil. The warning came after tank cars carrying Bakken oil exploded in three separate railroad accidents in Alabama, North Dakota, and Quebec. It’s a worrisome finding for the hundreds of communities that host loaded oil trains every week.

Let’s take a closer look at some particular issues with Bakken oil.

What’s different about Bakken oil?

Bakken oil is a type of “light sweet crude,” a relatively high quality oil that is easier to refine into commercial products, but also easier to ignite. A few decades ago, light-sweet crude was the dominant oil type in the US. Light oil is by no means new to the industry, but the recent boom in oil extraction in the Bakken and similar deposits elsewhere does represent a new and unexpected development for the industry.

What’s more, the large-scale rail transport of crude oil is a very recent phenomenon. From 2009 to 2012, for example, oil-by-rail shipments grew from fewer than 11,000 railcars nationally to well over 230,000. That astronomical growth has continued in 2013 and early 2014.

Is Bakken oil more flammable than crude oil from other sources?

Yes. This was confirmed by a the US Pipeline Hazardous Material Safety Administration (PHMSA) in a January 2 safety alert to the general public, emergency responders, and shippers and carriers of oil. PHMSA warns:

…recent derailments and resulting fires indicate that the type of crude oil being transported from the Bakken region may be more flammable than traditional heavy crude oil. Based on preliminary inspections conducted after recent derailments in North Dakota, Alabama, and Lac-Megantic, Quebec involving Bakken crude oil, PHMSA is reinforcing the requirement to properly test, characterize, classify, and where appropriate sufficiently degasify hazardous materials prior to and during transportation.

The PHMSA findings were corroborated by the industry-oriented Bakken Shale blog, calling it “flammable like gasoline.” The “flash point”—the lowest temperature at which ignition can occur—is lower for Bakken oil than for lower grade crude oils, which means that Bakken crude is particularly flammable. The post also warns that when flammable gases are dissolved in oil, the oil should be “degasified” before transportation.

What are these more flammable components in Bakken oil?

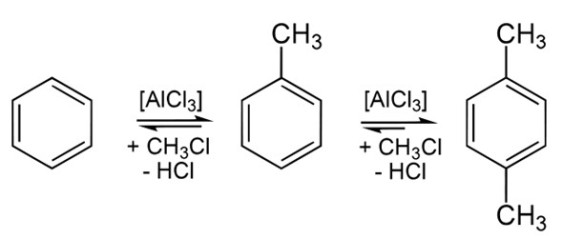

DeSmog Blog explains what is likely behind the explosions: Bakken oil contains volatile organic compounds (VOCs). As one piece of evidence, consider a permit application by Marquis Missouri Terminal LLC, the company that was to receive the oil from the BNSF train that exploded in North Dakota. In its application to construct a crude oil storage and receiving facility, Marquis reported that the oil was expected to contain Toluene, Xylene, Benzene, and Hexane—all VOCs. The estimated maximum weight of each component in the oil was 5 percent, 5 percent, 2 percent, and 3 percent, respectively, for a maximum total of 15 percent of the oil by weight.

A video conversation with actor Mark Ruffalo, founder of the organization Water Defense, and the group’s chief scientist Scott Smith, elaborates on the risks of Bakken oil. Smith obtained samples of Bakken oil in which he detected Benzene, Toluene, and Xylene. (His results are posted online by DeSmog Blog, here.)

Others have hypothesized that the culprit is hydrogen sulfide, a corrosive and extremely hazardous gas, that is present in high concentrations in some stocks of Bakken oil.

Why does Bakken crude contain more flammable components?

Scott Smith, the Water Defense chief scientist, explains the role played by the peculiar geology of the Bakken formation. Oil there is found “trapped” between layers of shale rock about 2 miles below ground with no surface outcropping that might allow volatile or gaseous compounds to escape. As a consequence, when the oil is extracted it often contains high levels of VOCs or other hazardous compounds. In fact, Smith estimates that up to 40 percent of the material in a tank car carrying Bakken oil may be volatile organic compounds, and therefore more flammable than the oil itself.

The North Dakota Department of Health has confirmed that Bakken oil contains more VOCs than initially expected, but federal PHMSA sampling data has not yet been released.

John Abbotts is a former Research Consultant to Sightline who occasionally submits material that Sightline staff turn into blog posts.

Update March 7, 2014: A newly released federal investigation found, among other things, that:

The flash point obtained for the occurrence crude oil samples was significantly less than 23 °C…

The occurrence crude oil’s properties were consistent with those of a light sweet crude oil, with volatility comparable to that of a condensate or gasoline product.

The occurrence crude oil samples were taken at atmospheric pressure. This could lead to an underestimation of the crude oil’s volatility due to evaporation loss of very light constituents.

The large quantities of spilled crude oil, the rapid rate of release, and the oil’s high volatility and low viscosity were likely the major contributors to the large post-derailment fireball and pool fire.

The occurrence crude oil contained concentrations of BTEX that were comparable to typical values reported for crude oils. This explains why concentrations of benzene and other VOCs well above exposure limits were detected at the derailment site.

Comments are closed.